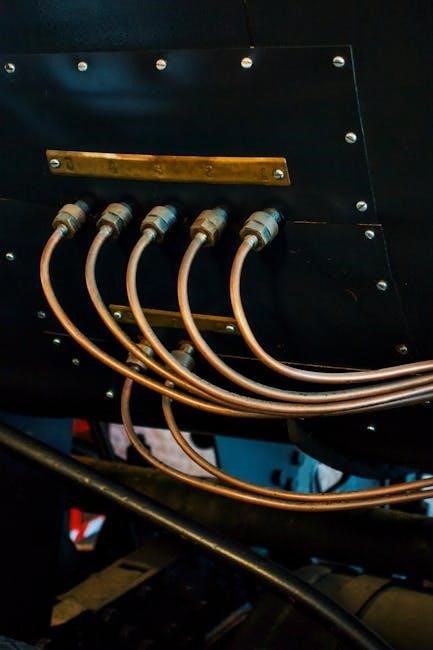

Hydraulic fittings are essential components that connect hoses, pipes, and tubes in hydraulic systems, ensuring efficient fluid flow and maintaining system pressure. They are available in various types, such as threaded, flanged, and push-on, designed to withstand high pressure and prevent leaks. These fittings are crucial for industrial machinery, construction equipment, and agricultural applications, offering durability and reliability in demanding environments.

Definition and Purpose of Hydraulic Fittings

Hydraulic fittings are components used to connect hydraulic hoses, pipes, and tubes in fluid power systems; Their primary purpose is to ensure efficient, leak-free connections, maintaining system pressure and flow. Available in types like threaded, flanged, and push-on, these fittings are designed to withstand high-pressure environments. They enable fluid to flow, change direction, or connect components like pumps, cylinders, and valves. Properly selected fittings are crucial for system performance, reliability, and safety in industrial, agricultural, and construction applications. Their durability and compatibility with various materials ensure optimal functionality across diverse hydraulic systems.

Importance of Hydraulic Fittings in Hydraulic Systems

Hydraulic fittings are crucial for ensuring leak-free connections and maintaining system pressure, which is essential for efficient fluid flow. They play a vital role in preventing downtime and reducing maintenance costs by providing reliable connections in high-pressure environments; Properly selected fittings enhance system performance, safety, and longevity, while incorrect choices can lead to leaks, contamination, or even system failure. Their ability to withstand harsh conditions and adapt to various applications makes them indispensable in industries like construction, agriculture, and manufacturing. By ensuring precise fluid direction and flow control, hydraulic fittings are fundamental to the overall functionality and efficiency of hydraulic systems.

Types of Hydraulic Fittings

Hydraulic fittings include threaded, flanged, weld, push-on, and quick-disconnect types, each designed for specific applications. They are made from materials like stainless steel and carbon steel for durability and corrosion resistance, ensuring reliable connections in high-pressure systems.

Threaded Fittings

Threaded hydraulic fittings are widely used for their simplicity and reliability. They feature either NPT (National Pipe Tapered) or JIC (Joint Industrial Council) threading, ensuring a secure connection. These fittings are ideal for low to medium pressure applications and are available in various configurations, such as elbows, tees, and couplings. Threaded fittings are easy to install and maintain, making them a popular choice in hydraulic systems. However, they can be prone to leakage if not properly sealed, emphasizing the importance of precise installation. Their versatility and cost-effectiveness make them a common solution in many industrial applications.

Flanged Fittings

Flanged hydraulic fittings are designed with a flat face and bolt holes, enabling secure connections in high-pressure systems. They are typically held in place by four bolts and conform to standards like SAE J518, offering reliability in demanding applications. Available in code 61 (3000 psi) and code 62 (6000 psi), these fittings are ideal for heavy-duty hydraulic systems. Flanged fittings provide excellent strength and resistance to leakage, making them suitable for use in construction equipment, oil rigs, and industrial machinery. Their robust design ensures durability, while the bolted connection allows for easy maintenance and system access, enhancing their practicality in various hydraulic setups.

Weld Fittings

Weld fittings are designed for permanent connections in hydraulic systems, offering a strong and leak-resistant seal. They are commonly used in high-pressure applications where reliability is critical. Made from durable materials like carbon steel and stainless steel, these fittings are ideal for heavy-duty machinery and industrial equipment. Weld fittings are particularly popular in the oil and gas industry, where they withstand harsh operating conditions. Their robust construction ensures long service life, minimizing the need for frequent replacements. By providing a permanent solution, weld fittings enhance system integrity and performance, making them a preferred choice for demanding hydraulic environments and large-scale industrial applications.

Push-On Fittings

Push-on fittings are a popular choice for hydraulic systems due to their ease of installation and reliable performance. These fittings feature a simple design that allows for quick connections without the need for tools or welding. They are commonly used in applications where frequent disassembly is required, such as in agricultural machinery and construction equipment. Push-on fittings are designed with a smooth, rounded edge that ensures a secure connection when pushed onto the hose or tube. This eliminates the risk of damage to the hose and provides a leak-resistant seal. Their versatility and convenience make them ideal for a wide range of hydraulic applications, offering both efficiency and durability.

Quick-Disconnect Fittings

Quick-disconnect fittings are designed for rapid and efficient connections in hydraulic systems, allowing for easy coupling and decoupling without tools. These fittings are ideal for applications requiring frequent changes, such as in agricultural machinery, construction equipment, and industrial plants. They feature a self-locking mechanism that ensures a secure and leak-resistant connection, while their durable construction withstands high pressure and harsh environments. Quick-disconnect fittings are widely used in industries where time-saving and flexibility are critical. Their ease of use, reliability, and versatility make them a preferred choice for hydraulic systems needing frequent maintenance or reconfiguration. They are available in various sizes and configurations to suit different hydraulic demands.

Materials Used for Hydraulic Fittings

Hydraulic fittings are made from materials like carbon steel, stainless steel, brass, and bronze, each offering unique strength, corrosion resistance, and durability for various hydraulic applications.

Carbon Steel Fittings

Carbon steel fittings are highly durable and versatile, making them ideal for high-pressure hydraulic applications; They offer excellent strength and resistance to wear and tear. These fittings are commonly used in industrial and construction equipment due to their ability to withstand harsh operating conditions. Carbon steel fittings are resistant to corrosion and can handle extreme temperatures, making them a reliable choice for demanding environments. They are available in various styles, including NPT and JIC configurations, ensuring compatibility with different hydraulic systems. Additionally, carbon steel fittings meet rigorous standards like SAE J518, ensuring superior performance and longevity in hydraulic connections.

Stainless Steel Fittings

Stainless steel fittings are renowned for their exceptional corrosion resistance and durability, making them ideal for hydraulic systems exposed to harsh environments. These fittings are resistant to chemicals, acids, and seawater, ensuring long-term performance in challenging conditions. Stainless steel fittings are commonly used in marine, chemical, and food processing industries. They offer high strength and resistance to extreme temperatures, maintaining system integrity under pressure; Available in various configurations, including NPT, JIC, and metric threads, stainless steel fittings provide versatility and reliability. Their ability to withstand corrosive elements makes them a preferred choice for applications requiring prolonged durability and minimal maintenance, ensuring optimal hydraulic system performance.

Brass and Bronze Fittings

Brass and bronze fittings are popular for their unique properties, offering excellent corrosion resistance and durability in hydraulic systems. Brass fittings are ideal for low-pressure applications and provide good resistance to wear and tear, making them suitable for general-purpose use. Bronze fittings, on the other hand, are stronger and more durable, often used in high-stress environments where reliability is critical. Both materials are resistant to corrosion, especially in water-based hydraulic systems, ensuring long-lasting performance. Their versatility and ability to withstand harsh conditions make brass and bronze fittings a reliable choice for various industrial and hydraulic applications, providing consistent and dependable service over time.

Applications of Hydraulic Fittings

Hydraulic fittings are indispensable in industrial machinery, construction equipment, and agricultural systems, ensuring reliable fluid flow and pressure maintenance. They are also critical in oil and gas operations.

Industrial Machinery

Hydraulic fittings are integral to industrial machinery, ensuring efficient fluid flow and maintaining system pressure. They connect hoses, pipes, and components like pumps and valves, enabling precise control. Constructed from durable materials such as carbon steel and stainless steel, these fittings withstand harsh environments and high-pressure demands. Their leak-resistant designs minimize downtime and enhance operational safety. Widely used in manufacturing, material handling, and heavy-duty applications, hydraulic fittings are essential for maintaining productivity and performance in industrial settings. Their reliability and compatibility with various systems make them a cornerstone of modern industrial machinery operations, ensuring smooth and efficient workflow across diverse applications.

Construction Equipment

Hydraulic fittings are vital in construction equipment, enabling efficient operation of machinery like excavators, bulldozers, and cranes. These fittings connect hydraulic hoses to components such as pumps, cylinders, and valves, ensuring precise fluid flow and pressure maintenance. Constructed from durable materials like stainless steel and carbon steel, they withstand the rigorous demands of construction sites. Their leak-resistant and high-pressure designs minimize downtime and enhance safety. By providing reliable connections, hydraulic fittings contribute to the productivity and longevity of construction equipment, allowing for smooth operation in demanding environments. Their role is crucial for maintaining the performance and efficiency of heavy-duty machinery in the construction industry.

Agricultural Machinery

Hydraulic fittings play a crucial role in agricultural machinery, ensuring the efficient operation of tractors, harvesters, and irrigation systems. These fittings connect hydraulic hoses to pumps, valves, and cylinders, enabling precise fluid flow and pressure control. Designed to withstand harsh outdoor conditions, they are often made from corrosion-resistant materials like stainless steel. Their durability and leak-resistant designs minimize downtime, ensuring continuous productivity in farming operations. Whether for powering hydraulic lifts or controlling water flow in irrigation systems, these fittings are essential for maintaining the performance and efficiency of agricultural equipment, supporting the demanding tasks of modern farming and food production.

Oil and Gas Industry

In the oil and gas industry, hydraulic fittings are critical for maintaining high-pressure systems and ensuring safe operations. They are used in drilling equipment, well control systems, and fluid transfer lines, where reliability is paramount. High-pressure ratings and resistance to corrosion are essential due to the harsh environments and exposure to corrosive substances. Stainless steel and carbon steel fittings are commonly utilized for their strength and durability. Proper installation and maintenance of these fittings are vital to prevent leaks and ensure uninterrupted operations, contributing to the efficiency and safety of oil and gas extraction and processing activities, where failure can have significant consequences.

Choosing the Right Hydraulic Fittings

Selecting the right hydraulic fittings involves considering pressure ratings, temperature compatibility, material durability, and thread matching to ensure leak-free connections and optimal system performance.

Pressure and Temperature Ratings

Pressure and temperature ratings are critical factors in selecting hydraulic fittings. Hydraulic systems operate under high pressure, requiring fittings rated for maximum pressure to prevent failure. Temperature ratings ensure fittings withstand extreme heat or cold without degradation. For example, stainless steel fittings are ideal for high-temperature applications, while carbon steel fittings are suitable for high-pressure environments. SAE J518 standards provide guidelines for pressure ratings, ensuring compatibility and safety. Ignoring these ratings can lead to system failure, leaks, or premature wear. Always consult manufacturer specifications to match fittings with the system’s operational conditions for safe and efficient performance.

Material Compatibility

Material compatibility is vital for hydraulic fittings to ensure durability and resistance to corrosion or chemical exposure. Common materials include carbon steel, stainless steel, brass, and bronze, each offering unique benefits. Carbon steel fittings are cost-effective and ideal for high-pressure applications, while stainless steel provides superior corrosion resistance, making it suitable for harsh environments. Brass and bronze fittings are often used in low-pressure systems due to their excellent corrosion resistance and ease of machining. Material selection must align with the hydraulic system’s operating conditions to prevent premature wear or failure. Always verify compatibility with fluids and environmental factors to ensure optimal performance and longevity.

Thread and Port Matching

Thread and port matching are critical for ensuring leak-free connections in hydraulic systems. Proper alignment of thread types, such as NPT, JIC, or SAE, ensures compatibility and prevents fluid leakage. Ports must also be sized and threaded correctly to match corresponding fittings, maintaining system integrity. Mismatched threads or ports can lead to leaks, reduced performance, or even system failure. Always verify thread standards and port configurations before installation to guarantee secure and efficient connections. This attention to detail is essential for maintaining the reliability and safety of hydraulic systems in industrial, construction, or agricultural applications. Correct matching ensures optimal fluid flow and minimizes downtime due to connection issues.

Leak-Resistant Designs

Leak-resistant designs in hydraulic fittings are engineered to ensure secure connections and minimize fluid leakage. These fittings often incorporate advanced sealing technologies, such as O-rings, gaskets, or tapered threads, to create a tight seal under pressure. Materials like stainless steel and brass are commonly used for their durability and resistance to corrosion, further enhancing leak resistance. Flanged fittings with multiple bolts distribute pressure evenly, reducing the risk of leaks. Additionally, some designs feature progressive ring bite connections, which create a keyed, leak-free tube connection. Proper material selection and design ensure long-term reliability, making leak-resistant hydraulic fittings essential for high-pressure applications in industries like oil, gas, and heavy machinery. Regular maintenance and correct installation further optimize their performance.

Installation and Maintenance Tips

Proper installation techniques ensure reliable performance and longevity of hydraulic fittings. Regular maintenance practices, such as inspections and cleaning, help prevent leaks and corrosion, optimizing system efficiency and safety.

Proper Installation Techniques

Proper installation of hydraulic fittings is crucial to ensure system reliability and performance. Always use calibrated tools to tighten fittings to the recommended torque specifications. Cleanliness is key—ensure all ports and threads are free from debris before assembly. Align components correctly to avoid misconnection. For threaded fittings, apply thread sealant to prevent leaks. When using push-on or quick-disconnect fittings, ensure the hose is properly seated. Refer to manufacturer guidelines for specific installation instructions. Conduct a pressure test after installation to verify integrity. Proper techniques minimize the risk of leaks, contamination, and premature wear, ensuring optimal hydraulic system functionality and safety.

Regular Maintenance Practices

Regular maintenance of hydraulic fittings is essential to prevent system failures and ensure longevity. Inspect fittings for signs of wear, corrosion, or leakage during routine checks. Clean dirt and debris from surfaces to avoid contamination. Replace O-rings and seals as recommended by manufacturers. Tighten loose connections without over-tightening, which can damage threads. Monitor system pressure and temperature, as excessive levels can stress fittings. Use compatible lubricants to protect against corrosion. Schedule periodic pressure testing to identify potential issues early. Proper maintenance practices reduce downtime, extend equipment life, and maintain hydraulic system efficiency, ensuring reliable performance in industrial and heavy-duty applications.

Standards and Certifications

Hydraulic fittings adhere to SAE J518 and ISO standards, ensuring design, testing, and performance compliance. Certifications guarantee reliability, durability, and safety in hydraulic systems.

SAE J518 Standard

The SAE J518 standard outlines specifications for flange adapters and hydraulically mounted flanges in high-pressure systems. It covers two main codes: Code 61 (3000 psi) and Code 62 (6000 psi), ensuring compatibility and safety. These standards define the dimensions, materials, and testing criteria for hydraulic fittings, guaranteeing reliability under extreme conditions. Compliance with SAE J518 is crucial for maintaining system integrity and preventing failures. The standard is widely adopted in industries like oil and gas, construction, and heavy machinery, where high-pressure hydraulic systems are essential. Adherence to SAE J518 ensures fittings meet rigorous quality and performance requirements.

ISO Standards for Hydraulic Fittings

ISO standards for hydraulic fittings ensure global compatibility and safety by defining dimensions, materials, and performance criteria. These standards address various aspects, including thread sizes, pressure ratings, and corrosion resistance. They apply to components like adapters, couplings, and connectors, ensuring seamless integration across different systems. Compliance with ISO standards is critical for manufacturers to meet international market demands. These standards also facilitate interchangeability and reliability, reducing the risk of system failures. By adhering to ISO guidelines, hydraulic fittings meet stringent quality benchmarks, making them suitable for diverse applications, from industrial machinery to mobile equipment.

Suppliers and Manufacturers

Prominent global suppliers like Brennan Industries and Parker offer high-quality hydraulic fittings, ensuring reliability and durability. These manufacturers provide a wide range of products, meeting diverse industry needs.

Leading Global Suppliers

Brennan Industries, a global leader, offers over 120,000 hydraulic fitting styles, ensuring unmatched variety and quality. Parker Hannifin is renowned for innovative solutions, while Enerpac specializes in high-pressure fittings. Discount Hydraulic Hose provides affordable, durable options, catering to diverse industries. These suppliers prioritize material quality, precision engineering, and reliability, meeting stringent industry standards. Their extensive product ranges include adapters, couplings, and connectors, designed for seamless integration into hydraulic systems. With global distribution networks, these suppliers ensure timely delivery and exceptional customer support, making them trusted partners for hydraulic system needs worldwide.

Quality Assurance and Reliability

Leading manufacturers prioritize rigorous quality assurance processes to ensure hydraulic fittings meet global standards. Brennan Industries, for instance, uses aerospace-quality manufacturing and full material traceability. Fittings undergo extensive testing for pressure, temperature, and durability. ISO certifications guarantee compliance with international standards, while corrosion-resistant coatings enhance longevity. Suppliers like Parker Hannifin and Enerpac emphasize precision engineering and premium materials. Regular audits and advanced testing protocols ensure consistency and reliability. These practices minimize the risk of leaks or failures, providing users with trustworthy solutions for demanding hydraulic applications. High-quality fittings are designed to withstand harsh environments, ensuring optimal performance and safety in critical systems.

Hydraulic fittings are crucial for efficient fluid flow and system reliability. Their durability and variety ensure they meet diverse industrial needs, making them indispensable in modern machinery.

Hydraulic fittings are critical components in fluid power systems, ensuring secure connections and efficient fluid flow. They come in various types, such as threaded, flanged, and push-on, each designed for specific applications. Materials like carbon steel, stainless steel, and brass offer durability and resistance to corrosion. Proper selection based on pressure, temperature, and compatibility is vital for system reliability. Standards like SAE J518 and ISO certifications ensure quality and performance. Regular maintenance and correct installation techniques are essential to prevent leaks and extend service life. With advancements in technology, future trends may focus on leak-resistant designs and high-performance materials to meet evolving industrial demands;

Future Trends in Hydraulic Fittings

Future trends in hydraulic fittings emphasize advanced materials, leak-resistant designs, and high-pressure capabilities. Innovations in stainless steel and corrosion-resistant coatings are expected to dominate, ensuring longevity in harsh environments. Smart fittings with sensors for real-time monitoring are emerging, enabling predictive maintenance and improved efficiency. Lightweight materials, such as titanium, are gaining traction for their strength-to-weight ratio. Manufacturers are also focusing on sustainability, developing eco-friendly options. Additionally, the adoption of universal standards like SAE J518 and ISO certifications will drive global compatibility. As industries evolve, hydraulic fittings will continue to adapt, offering superior performance, durability, and reliability to meet the demands of modern hydraulic systems.